Njengamanje, isizukulwane sesithathu sama-semiconductors sibuswa yii-silicon carbide. Esimisweni sezindleko zamadivayisi ayo, i-substrate ilandisa ngama-47%, futhi i-epitaxy ibalwa ngama-23%. Zombili zihlangene zibalelwa ku-70%, okuyingxenye ebaluleke kakhulu ye-i-silicon carbideuchungechunge lwemboni yokukhiqiza idivayisi.

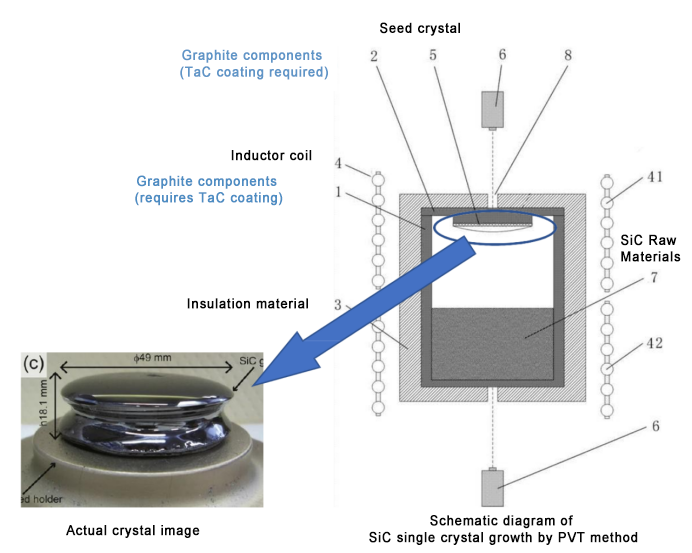

Indlela evame ukusetshenziswa yokulungiselelai-silicon carbideIkristalu eyodwa iyindlela ye-PVT (i-physical vapor transport). Umgomo uwukwenza izinto zokusetshenziswa endaweni yokushisa ephezulu kanye nekristalu yembewu endaweni enezinga lokushisa eliphansi. Izinto zokusetshenziswa ekushiseni okuphezulu ziyabola futhi zikhiqize ngokuqondile izinto zesigaba segesi ngaphandle kwesigaba se-liquid. Lezi zinto zesigaba segesi zithuthelwa ku-crystal yembewu ngaphansi kokushayela kwe-axial temperature gradient, futhi i-nucleate futhi ikhule ku-seed crystal ukwenza i-silicon carbide single crystal. Njengamanje, izinkampani zakwamanye amazwe ezifana neCree, II-VI, SiCrystal, Dow kanye nezinkampani zasekhaya ezifana neTianyue Advanced, Tianke Heda, kanye neCentury Golden Core zonke zisebenzisa le ndlela.

Kunezinhlobo ezingaphezu kuka-200 zekristalu ye-silicon carbide, futhi ukulawula okunembe kakhulu kuyadingeka ukuze kukhiqizwe ifomu lekristalu elilodwa elidingekayo (okujwayelekile kuyifomu lekristalu elingu-4H). Ngokuvumelana ne-prospectus ye-Tianyue Advanced, isivuno se-crystal rod yenkampani ngo-2018-2020 futhi i-H1 2021 yayingama-41%, 38.57%, 50.73% no-49.90% ngokulandelana, kanti isivuno se-substrate sasingu-72.61%, 5, 7, 7%, 75% no-7%. ngokulandelana. Isivuno esiphelele njengamanje singama-37.7% kuphela. Uma sithatha indlela ye-PVT evamile njengesibonelo, isivuno esiphansi sibangelwa ikakhulukazi lobunzima obulandelayo ekulungiseleleni i-substrate ye-SiC:

1. Ubunzima ekulawuleni izinga lokushisa endaweni: Izinduku zekristalu ze-SiC zidinga ukukhiqizwa ekushiseni okuphezulu okungu-2500 ℃, kuyilapho amakristalu e-silicon edinga u-1500 ℃ kuphela, ngakho-ke kudingeka iziko ezikhethekile zekristalu eyodwa, futhi izinga lokushisa lokukhula lidinga ukulawulwa ngokunembile ngesikhathi sokukhiqiza. , okunzima kakhulu ukuyilawula.

2. Isivinini sokukhiqiza esinensayo: Izinga lokukhula kwezinto ezivamile ze-silicon ngu-300 mm ngehora, kodwa ikristalu elilodwa le-silicon carbide lingakhula kuphela ama-microns angu-400 ngehora, okuwumehluko ocishe uphindwe izikhathi ezingu-800.

3. Izidingo eziphakeme zamapharamitha womkhiqizo omuhle, kanye nokuvunwa kwebhokisi elimnyama kunzima ukulawula ngesikhathi: Imingcele eyinhloko yama-wafers e-SiC ihlanganisa ukuminyana kwe-microtube, ukuminyana kokuhlukaniswa, ukumelana, i-warpage, ukuhwaqeka kwendawo, njll. Phakathi nenqubo yokukhula kwekristalu, kuba kudingekile ukuze ulawule ngokunembile amapharamitha afana ne-silicon-carbon ratio, i-gradient yokukhula kwezinga lokushisa, izinga lokukhula kwekristalu, nokucindezela kokugeleza komoya. Uma kungenjalo, ukufakwa kwe-polymorphic kungenzeka kwenzeke, okuholela kumakristalu angafaneleki. Ebhokisini elimnyama le-graphite crucible, akunakwenzeka ukubona isimo sokukhula kwekristalu ngesikhathi sangempela, futhi ukulawulwa kwensimu yokushisa okunembe kakhulu, ukufaniswa kwezinto ezibonakalayo, nokuqoqwa kokuhlangenwe nakho kuyadingeka.

4. Ubunzima ekwandiseni ikristalu: Ngaphansi kwendlela yokuthutha yesigaba segesi, ubuchwepheshe bokunwetshwa kwe-SiC crystal ukukhula bunzima kakhulu. Njengoba usayizi wekristalu ukhula, ubunzima bayo bokukhula bukhula kakhulu.

5. Isivuno esivamile esiphansi: Isivuno esiphansi ngokuyinhloko sakhiwe izixhumanisi ezimbili: (1) Isivuno se-Crystal rod = ukuphuma kwe-crystal rod semiconductor-grade-(semiconductor-grade crystal rod output + non-semiconductor-grade crystal rod output) × 100%; (2) Isivuno se-substrate = ukukhishwa kwe-substrate okufanelekile/(okuphumayo kwe-substrate okufanelekile + ukuphuma kwe-substrate okungafanelekile) × 100%.

Ekulungiseleleni izinga eliphezulu kanye nesivuno esiphezului-silicon carbide substrates, umgogodla udinga izinto ezingcono zensimu ezishisayo ukuze ulawule ngokunembile izinga lokushisa lokukhiqiza. Amakhithi e-thermal field crucible kits asetshenziswayo njengamanje ayingxenye yesakhiwo se-graphite ehlanzekile kakhulu, esetshenziselwa ukushisa nokuncibilikisa i-carbon powder kanye ne-silicon powder futhi ihlale ifudumele. Izinto ze-graphite zinezici zamandla akhethekile aphezulu kanye ne-modulus ethize, ukumelana nokushaqeka okuhle kokushisayo nokumelana nokugqwala, kodwa zinemibi ye-oxidized kalula ezindaweni ezinezinga eliphezulu lokushisa komoyampilo, ezingamelani ne-ammonia, kanye nokungazweli kahle kokuklwebheka. Ngenqubo ye-silicon carbide ukukhula kwekristalu eyodwa kanyei-silicon carbide epitaxial waferukukhiqizwa, kunzima ukuhlangabezana nezidingo zabantu eziqinile zokusebenzisa izinto ze-graphite, ezikhawulela kakhulu ukuthuthukiswa nokusebenza kwayo okungokoqobo. Ngakho-ke, izambatho ezisezingeni eliphezulu ezifana ne-tantalum carbide seziqalile ukuvela.

2. Izici zeI-Tantalum Carbide Coating

I-ceramic ye-TaC inendawo yokuncibilika efika ku-3880℃, ubulukhuni obuphezulu (Mohs hardness 9-10), ukuguquguquka okukhulu kwe-thermal (22W·m-1·K−1), amandla amakhulu okugoba (340-400MPa), nokunwetshwa okuncane kokushisa i-coefficient (6.6×10−6K−1), futhi ibonisa ukuzinza okuhle kakhulu kwe-thermochemical kanye nezakhiwo ezinhle kakhulu zomzimba. Inokuhambisana okuhle kwamakhemikhali nokuhambisana kwemishini ne-graphite kanye nezinto ezihlanganisiwe ze-C/C. Ngakho-ke, ukunamathela kwe-TaC kusetshenziswa kakhulu ekuvikelweni okushisayo kwe-aerospace, ukukhula kwekristalu eyodwa, izinto zikagesi zamandla, kanye nemishini yezokwelapha.

I-TaC-coatedI-graphite inokumelana nokugqwala kwamakhemikhali okungcono kune-graphite engenalutho noma i-graphite ehlanganiswe ne-SiC, ingasetshenziswa ngokuzinza emazingeni okushisa aphezulu angu-2600 °, futhi ayisabelani nezinto eziningi zensimbi. Iwucwecwe olungcono kakhulu ekukhuleni kwekristalu eyodwa ye-semiconductor yesizukulwane sesithathu kanye nezimo ze-wafer etching. Kungathuthukisa kakhulu ukulawulwa kwezinga lokushisa nokungcola ohlelweni futhi kulungiseleleizinga eliphezulu le-silicon carbide wafersnokuhlobeneama-wafers e-epitaxial. Ifaneleka ngokukhethekile ukukhulisa ikristalu eyodwa ye-GaN noma ye-AlN ngemishini ye-MOCVD nokukhulisa amakristalu e-SiC eyodwa ngemishini ye-PVT, futhi ikhwalithi yamakristalu angawodwa akhulile ithuthukiswa kakhulu.

III. Izinzuzo Tantalum Carbide Coated Amadivayisi

Ukusetshenziswa kwe-Tantalum Carbide TaC coating kungaxazulula inkinga ye-crystal edge defect futhi kuthuthukise ikhwalithi yokukhula kwekristalu. Kungenye yezinkomba zezobuchwepheshe "zokukhula ngokushesha, ukukhula okushubile, nokukhula isikhathi eside". Ucwaningo lwemboni luphinde lwabonisa ukuthi i-Tantalum Carbide Coated Graphite Crucible ingafinyelela ukushisisa okufanayo okufanayo, ngaleyo ndlela inikeze ukulawulwa kwenqubo okuhle kakhulu kokukhula kwekristalu eyodwa ye-SiC, ngaleyo ndlela yehlise kakhulu amathuba okwakheka kwe-polycrystalline emaphethelweni amakristalu e-SiC. Ngaphezu kwalokho, i-Tantalum Carbide Graphite Coating inezinzuzo ezimbili ezinkulu:

(I) Ukunciphisa Ukukhubazeka kwe-SiC

Mayelana nokulawula ukukhubazeka kwekristalu eyodwa ye-SiC, kuvame ukuba nezindlela ezintathu ezibalulekile. Ngaphezu kokuthuthukisa amapharamitha okukhula nezinto zomthombo wekhwalithi ephezulu (njenge-SiC source powder), ukusebenzisa i-Tantalum Carbide Coated Graphite Crucible nakho kungafinyelela ikhwalithi enhle yekristalu.

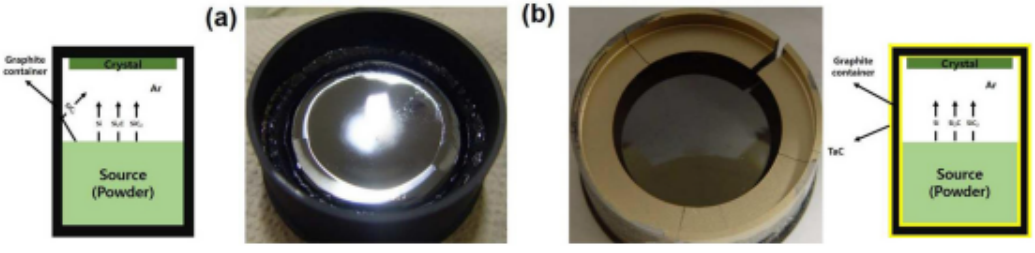

Umdwebo ohleliwe we-graphite crucible evamile (a) kanye ne-TAC coated crucible (b)

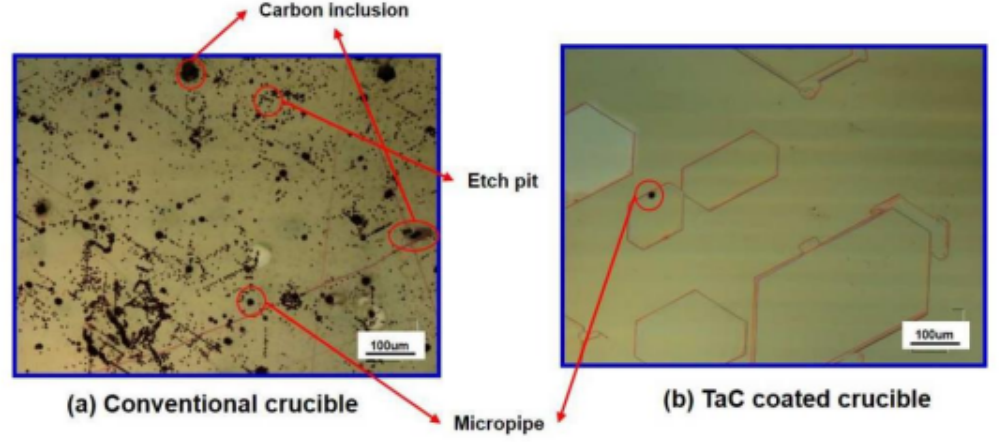

Ngokocwaningo olwenziwa yiNyuvesi yaseMpumalanga Yurophu eKorea, ukungcola okuyinhloko ekukhuleni kwekristalu ye-SiC kuyi-nitrogen, futhi i-tantalum carbide coated graphite crucibles ingakhawulela ngempumelelo ukufakwa kwe-nitrogen yamakristalu e-SiC, ngaleyo ndlela kunciphise ukukhiqizwa kokukhubazeka okufana namapayipi amancane nokuthuthukisa ikristalu. izinga. Ucwaningo luye lwabonisa ukuthi ngaphansi kwezimo ezifanayo, ukugxilwa kwenkampani ye-SiC wafers ekhulile kuma-graphite crucibles ajwayelekile kanye ne-TAC coated crucibles cishe i-4.5 × 1017 / cm kanye ne-7.6 × 1015 / cm, ngokulandelana.

Ukuqhathaniswa kokukhubazeka kumakristalu awodwa e-SiC akhule kuma-graphite crucibles avamile (a) kanye nezikhisi ezimboziwe ze-TAC (b)

(II) Ukuthuthukisa impilo ye-graphite crucibles

Njengamanje, izindleko zamakristalu e-SiC ziye zahlala ziphakeme, lapho izindleko ze-graphite consumables zibalelwa ku-30%. Isihluthulelo sokunciphisa izindleko ze-graphite consumables ukwandisa impilo yayo yesevisi. Ngokusho kwedatha evela eqenjini labacwaningi baseBrithani, i-tantalum carbide coating inganweba impilo yesevisi yezingxenye ze-graphite ngo-30-50%. Ngokwalesi sibalo, ukufaka kuphela i-tantalum carbide camera graphite kunganciphisa izindleko zamakristalu e-SiC ngo-9% -15%.

4. Inqubo yokulungiselela i-Tantalum carbide coating

Izindlela zokulungiselela ukunamathela kwe-TaC zingahlukaniswa ngezigaba ezintathu: indlela yesigaba esiqinile, indlela yesigaba soketshezi kanye nendlela yesigaba segesi. Indlela yesigaba esiqinile ikakhulukazi ihlanganisa indlela yokunciphisa kanye nendlela yamakhemikhali; indlela yesigaba se-liquid ihlanganisa indlela kasawoti encibilikisiwe, indlela ye-sol-gel (i-Sol-Gel), indlela ye-slurry-sintering, indlela yokufafaza nge-plasma; indlela yesigaba segesi ihlanganisa i-chemical vapor deposition (CVD), i-chemical vapor infiltration (CVI) kanye ne-physical vapor deposition (PVD). Izindlela ezehlukene zinezinzuzo zazo kanye nokubi. Phakathi kwazo, i-CVD iyindlela evuthiwe futhi esetshenziswa kabanzi yokulungiselela ukumbozwa kwe-TaC. Ngokuthuthukiswa okuqhubekayo kwenqubo, izinqubo ezintsha ezifana nokufaka umhwamuko wamakhemikhali ngocingo olushisayo kanye nokufaka umhwamuko wamakhemikhali okusizwa yi-ion kuye kwasungulwa.

Izinto eziguquliwe ze-TaC ezisekelwe kukhabhoni ikakhulukazi zifaka i-graphite, i-carbon fibre, nezinto eziyinhlanganisela ye-carbon/carbon. Izindlela zokulungiselela ukunamathela kwe-TaC ku-graphite zifaka ukufuthwa kwe-plasma, i-CVD, i-slurry sintering, njll.

Izinzuzo zendlela ye-CVD: Indlela ye-CVD yokulungisa okunamathelayo kwe-TaC isuselwe ku-tantalum halide (TaX5) njengomthombo we-tantalum kanye ne-hydrocarbon (CnHm) njengomthombo wekhabhoni. Ngaphansi kwezimo ezithile, zibola zibe u-Ta no-C ngokulandelanayo, bese ziyasabelana ukuze zithole okokunamathela kwe-TaC. Indlela ye-CVD ingenziwa ekushiseni okuphansi, okungagwema amaphutha nokunciphisa izakhiwo zemishini ezibangelwa ukulungiswa kokushisa okuphezulu noma ukwelashwa kwezingubo ngezinga elithile. Ukwakheka kanye nokwakheka kwe-coating kuyalawuleka, futhi kunezinzuzo zokuhlanzeka okuphezulu, ukuminyana okuphezulu, nokuqina okufanayo. Okubaluleke nakakhulu, ukwakheka nokwakheka kwezingubo ze-TaC ezilungiswe yi-CVD kungaklanywa futhi kulawulwe kalula. Kuyindlela evuthiwe futhi esetshenziswa kabanzi yokulungisa okokugcotshwa kwe-TaC kwekhwalithi ephezulu.

Izinto ezibalulekile ezinomthelela wenqubo zihlanganisa:

A. Izinga lokugeleza kwegesi (umthombo we-tantalum, igesi ye-hydrocarbon njengomthombo wekhabhoni, igesi yenkampani yenethiwekhi, igesi ehlanjululwe i-Ar2, igesi enciphisa i-H2): Ushintsho lwezinga lokugeleza kwegesi lunomthelela omkhulu endaweni yezinga lokushisa, inkambu yokucindezela, nenkundla yokugeleza kwegesi ikamelo lokusabela, okuholela ekushintsheni ekubunjweni, ekubunjweni, nasekusebenzeni kwe-coating. Ukwenyusa izinga lokugeleza kwe-Ar kuzonciphisa izinga lokukhula kokumboza futhi kunciphise usayizi wokusanhlamvu, kuyilapho isilinganiso se-molar mass ye-TaCl5, H2, ne-C3H6 sithinta ukwakheka kokumboza. Isilinganiso se-molar se-H2 kuya ku-TaCl5 ngu-(15-20):1, okufanele kakhulu. Isilinganiso se-molar se-TaCl5 ukuya ku-C3H6 ngokwethiyori sisondele ku-3:1. I-TaCl5 eyeqile noma i-C3H6 izodala ukwakheka kwe-Ta2C noma i-carbon yamahhala, kuthinte ikhwalithi ye-wafer.

B. Izinga lokushisa le-deposition: Uma izinga lokushisa liphezulu liphezulu, izinga lokubeka liyashesha, usayizi wohlamvu likhulu, kanye nokumbozeka okukhulu. Ukwengeza, izinga lokushisa nesivinini sokubola kwe-hydrocarbon ku-C kanye ne-TaCl5 ukubola ku-Ta kuhlukile, futhi u-Ta no-C maningi amathuba okuba kwakhe i-Ta2C. Izinga lokushisa linomthelela omkhulu ekunambeni kwe-TaC okokusebenza kwekhabhoni eguquliwe. Njengoba izinga lokushisa le-deposition likhuphuka, izinga lokubeka liyakhula, usayizi wezinhlayiyana uyakhula, futhi ukwakheka kwezinhlayiyana kushintsha kusuka ku-spherical kuya ku-polyhedral. Ukwengeza, uma izinga lokushisa liphakeme, ukubola kwe-TaCl5 kushesha, ukuncipha kwe-C kuzoba kukhulu, ingcindezi enamathelayo, kanye nokuqhekeka kuzokwenziwa kalula. Kodwa-ke, izinga lokushisa eliphansi le-deposition lizoholela ekusebenzeni kahle kwe-coating, isikhathi eside sokubeka, kanye nezindleko zempahla eluhlaza.

C. Ukucindezela kwe-deposition: Ukucindezela kwe-deposition kuhlobene eduze namandla amahhala omhlaba wezinto ezibonakalayo futhi kuzothinta isikhathi sokuhlala kwegesi ekamelweni lokusabela, ngaleyo ndlela kuthinte isivinini se-nucleation kanye nosayizi wezinhlayiyana zokugqoka. Njengoba ingcindezi yokubeka inyuka, isikhathi sokuhlala kwegesi siba side, ama-reactants anesikhathi esengeziwe sokusabela kwe-nucleation, izinga lokusabela liyakhula, izinhlayiya ziba zinkulu, futhi ukumboza kuba mkhulu; ngokuphambene, njengoba ingcindezi yokubeka iyancipha, isikhathi sokuhlala segesi yokusabela sifushane, izinga lokusabela liyancipha, izinhlayiya ziba zincane, futhi ukugqoka kuba mncane, kodwa ingcindezi yokubeka inomphumela omncane esakhiweni sekristalu nokubunjwa kwe-coating.

V. Umkhuba wokuthuthuka we-tantalum carbide coating

I-thermal expansion coefficient ye-TaC (6.6×10−6K−1) ithe ukuhluka kuleyo yezinto ezisuselwa kukhabhoni njengegraphite, i-carbon fibre, kanye nezinto eziyinhlanganisela ye-C/C, okwenza izimbobo ze-TaC zesigaba esisodwa zithambekele ekuqhekekeni futhi ewa. Ukuze kuqhutshekwe kuthuthukiswe ukumelana ne-oxidation, izinga lokushisa eliphezulu lokuzinza, kanye nokumelana nokugqwala kwamakhemikhali okuphezulu kwezinga lokushisa kwezingubo ze-TaC, abacwaningi benze ucwaningo ngezinhlelo zokumboza ezifana nezinhlelo zokuhlanganisa eziyinhlanganisela, izinhlelo eziqinile zokuhlanganisa isixazululo, kanye ne-gradient. izinhlelo zokumboza.

Uhlelo lokuhlanganisa oluyinhlanganisela luwukuvala imifantu yesigqoko esisodwa. Ngokujwayelekile, ezinye izimbotshana zethulwa endaweni engaphezulu noma yangaphakathi ye-TaC ukuze kwakheke uhlelo lokuhlanganisa oluyinhlanganisela; isixazululo esiqinile sokuqinisa isistimu yokuhlanganisa i-HfC, i-ZrC, njll. inesakhiwo se-cubic esigxile ebusweni esifanayo njenge-TaC, futhi ama-carbide amabili angancibilika ngokungenamkhawulo komunye nomunye ukuze akhe isakhiwo sesisombululo esiqinile. I-Hf(Ta)C enamathelayo ayiqhekeki futhi inokunamathela okuhle kokuhlanganisiwe kwe-C/C. I-coating inokusebenza okuhle kakhulu kwe-anti-ablation; i-gradient coating system coating gradient ibhekisela ekugxilweni kwengxenye yokwemboza ngokuhambisana nokuqina kwayo. Isakhiwo singanciphisa ukucindezeleka kwangaphakathi, sithuthukise ukungafani kwama-coefficients wokunweba okushisayo, futhi sigweme imifantu.

(II) Imikhiqizo yedivayisi yokuhlanganisa i-Tantalum carbide

Ngokwezibalo kanye nezibikezelo ze-QYR (Hengzhou Bozhi), ukuthengiswa kwemakethe ye-tantalum carbide coating yomhlaba wonke ngo-2021 kwafinyelela ku-US$1.5986 million (ngaphandle kwemikhiqizo yedivayisi yokuhlanganisa ye-tantalum carbide ye-Cree), futhi kusesekuqaleni. izigaba zokuthuthukiswa kwezimboni.

1. Amaringi okunweba okucwebezelayo adingekayo ekukhuleni kwekristalu: Ngokusekelwe kumaziko okukhula kwekristalu angu-200 ibhizinisi ngalinye, isabelo semakethe samadivayisi ahlanganiswe ne-TaC adingwa izinkampani ezikhulisa amakristalu angu-30 cishe singamayuan ayizigidi eziyizinkulungwane ezingu-4.7.

2. Amathreyi e-TaC: Ithreyi ngalinye lingaphatha amawafa ama-3, ithreyi ngalinye lingasetshenziswa inyanga engu-1, futhi ithreyi elilodwa liyasetshenziswa kuwo wonke amawafa ayi-100. Ama-wafer ayizigidi ezi-3 adinga amathreyi e-TaC angu-30,000, ithreyi ngalinye linezingcezu ezingaba ngu-20,000, futhi cishe izigidi ezingu-600 ziyadingeka unyaka ngamunye.

3. Ezinye izimo zokunciphisa i-carbon. Okufana ne-high-temperature furnace lining, i-CVD nozzle, amapayipi esithandweni somlilo, njll., cishe izigidi eziyi-100.

Isikhathi sokuthumela: Jul-02-2024