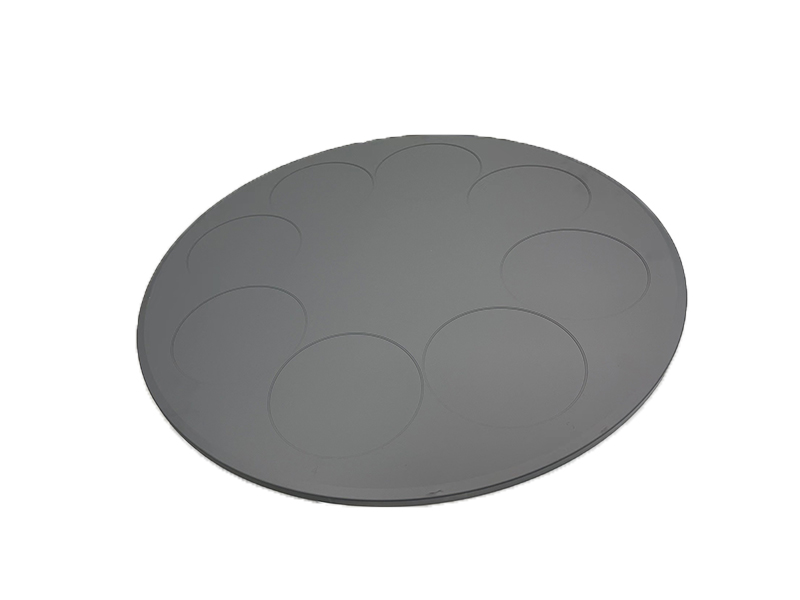

I-Solid Silicon Carbide(SiC) Etching Rings ehlinzekwa yi-Semicera ikhiqizwa ngendlela ye-Chemical Vapor Deposition (CVD) futhi iwumphumela ovelele emkhakheni wezinhlelo zokusebenza zenqubo yokubhala ngokunemba. Lawa ma-Solid Silicon Carbide (SiC) Etching Rings aziwa ngobulukhuni bawo obuhle kakhulu, ukuqina okushisayo nokumelana nokugqwala, futhi ikhwalithi ephezulu yezinto ezibonakalayo iqinisekiswa ukuhlanganiswa kwe-CVD.

Idizayinelwe ngokukhethekile izinqubo zokufaka, i-Solid Silicon Carbide(SiC) Etching Rings' isakhiwo esimangelengele kanye nempahla eyingqayizivele idlala indima ebalulekile ekuzuzeni ukunemba nokwethembeka. Ngokungafani nezinto zendabuko, ingxenye ye-SiC eqinile inokuqina okungenakuqhathaniswa nokumelana nokugqoka, okuyenza ibe yingxenye ebalulekile ezimbonini ezidinga ukunemba nempilo ende.

I-Solid Silicon Carbide (SiC) Etching Izindandatho zethu zenziwa ngokunemba futhi zilawulwa ikhwalithi ukuze kuqinisekiswe ukusebenza kwazo okuphezulu nokuthembeka. Kungakhathaliseki ukuthi kusekwenziweni kwe-semiconductor noma kwezinye izinkambu ezihlobene, lezi Ndandatho Zokunamathisela ze-Solid Silicon Carbide(SiC) zingahlinzeka ngokusebenza okuzinzile kwe-etching kanye nemiphumela emihle kakhulu yokuqopha.

Uma unentshisekelo ku-Solid Silicon Carbide (SiC) Etching Ring yethu, sicela usithinte. Ithimba lethu lizokunikeza imininingwane yomkhiqizo enemininingwane kanye nokwesekwa kochwepheshe ukuze uhlangabezane nezidingo zakho. Sibheke ngabomvu ukusungula ubambiswano lwesikhathi eside nawe futhi sikhuthaze ngokubambisana ukuthuthukiswa kwemboni.

✓Ikhwalithi ephezulu emakethe yaseChina

✓Isevisi enhle njalo kuwe, amahora angu-7*24

✓Idethi emfishane yokulethwa

✓I-MOQ encane yamukelekile futhi yamukelwe

✓Amasevisi angokwezifiso

I-Epitaxy Growth Susceptor

Amawafa e-silicon/silicon carbide adinga ukudlula ezinqubweni eziningi okufanele asetshenziswe kumishini kagesi. Inqubo ebalulekile i-silicon/sic epitaxy, lapho amawafa e-silicon/sic athwalwa khona ngesisekelo segraphite. Izinzuzo ezikhethekile ze-Semicera's silicone carbide-coated graphite base zifaka ukuhlanzeka okuphezulu kakhulu, ukunamathela okufanayo, nempilo yesevisi ende kakhulu. Futhi banokuphikiswa okuphezulu kwamakhemikhali kanye nokuzinza kokushisa.

Ukukhiqizwa kwe-chip ye-LED

Ngesikhathi sokumbozwa okubanzi kwe-reactor ye-MOCVD, isisekelo seplanethi noma umthwali uhambisa i-wafer ye-substrate. Ukusebenza kwezinto eziyisisekelo kunethonya elikhulu kwikhwalithi yokugqoka, okubuye kuthinte izinga le-scrap ye-chip. Isisekelo esihlanganiswe ne-silicon carbide se-Semicera sinyusa ukusebenza kahle kokukhiqizwa kwamawafa e-LED ekhwalithi ephezulu futhi sinciphisa ukuchezuka kwamaza. Siphinde sinikeze izingxenye ezengeziwe ze-graphite zazo zonke iziphehlisi ze-MOCVD ezisetshenziswayo njengamanje. Singakwazi ukugqoka cishe noma iyiphi ingxenye nge-silicon carbide coating, noma ngabe ububanzi bengxenye bufika ku-1.5M, sisengakwazi ukugqoka nge-silicon carbide.

Inkambu yeSemiconductor, Inqubo Yokusabalalisa Kwe-oxidation, njll.

Enqubweni ye-semiconductor, inqubo yokunwetshwa kwe-oxidation idinga ukuhlanzeka okuphezulu komkhiqizo, futhi kwa-Semicera sinikeza inkambiso nezinsizakalo zokumboza ze-CVD zeningi lezingxenye ze-silicon carbide.

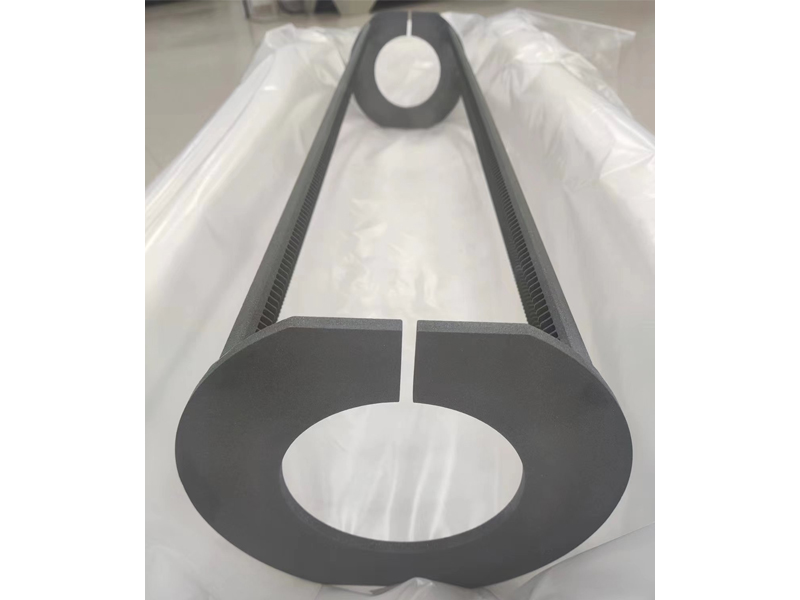

Isithombe esilandelayo sibonisa udaka lwe-silicon carbide olucutshungulwe kahle lwe-Semicea kanye neshubhu le-silicon carbide furnace elihlanzwa ku-1000-izingaengenalo uthuliigumbi. Abasebenzi bethu basebenza ngaphambi kokugqoka. Ukuhlanzeka kwe-silicon carbide yethu kungafinyelela ku-99.99%, futhi ubumsulwa be-sic coating bukhulu kuno-99.99995%.

I-Raw Silicon Carbide Paddle kanye ne-SiC Process Tube in Cleaing

I-Silicon Carbide Wafer Boat CVD SiC Coated