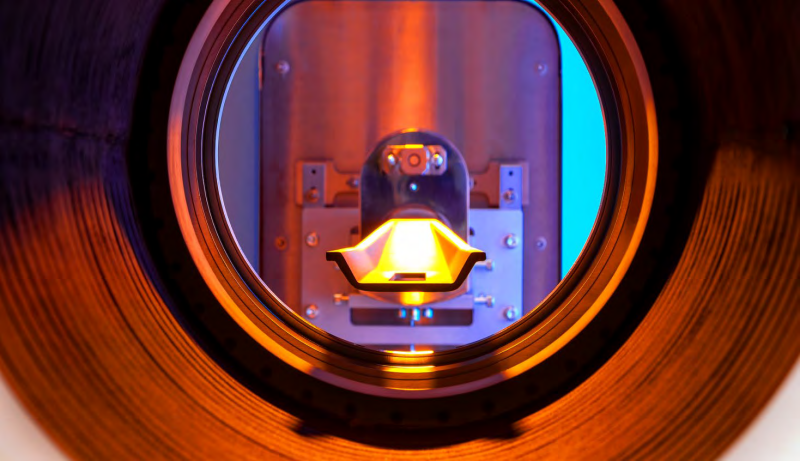

I-Semicera iveza inkambiso yekhwalithi ephezului-silicon carbide cantilever paddlesyakhelwe ukuphakamisa izinqubo zokukhiqiza i-semiconductor. I-innovativeIsigwedlo se-SiCidizayini iqinisekisa ukuqina okukhethekile kanye nokumelana nokushisa okuphezulu, okuyenza ibe yingxenye ebalulekile yokuphatha ama-wafer ezindaweni eziyinselele ezinezinga lokushisa eliphezulu.

II-silicon carbide paddleyakhelwe ukumelana nemijikelezo eshisayo ngenkathi igcina ubuqotho besakhiwo, iqinisekisa ukuthuthwa kwe-wafer okuthembekile phakathi nezigaba ezibucayi zokukhiqizwa kwe-semiconductor. Ngamandla aphezulu emishini, lokhuisikebhe esilucwecwanakunciphisa ubungozi bokulimala kwama-wafers, okuholela ekuvuneni okuphezulu kanye nekhwalithi yokukhiqiza engaguquki.

Enye yezinto ezintsha ezibalulekile ku-Semicera's SiC paddle ilele ezinkethweni zayo zokuklama ngokwezifiso. Iklanyelwe ukuhlangabezana nezidingo ezithile zokukhiqiza, i-paddle inikeza ukuguquguquka ekuhlanganisweni nokusethwa kwemishini ehlukahlukene, okuyenza ibe yisixazululo esifanelekile sezinqubo zokwenziwa zesimanje. Ukwakhiwa okungasindi kodwa okuqinile kwenza kube lula ukuphatha futhi kunciphisa isikhathi sokusebenza, okunomthelela ekuthuthukisweni kokusebenza kahle ekukhiqizeni kwe-semiconductor.

Ngaphezu kwezakhiwo zayo ezishisayo nezemishini, i-I-silicon carbide paddleinikeza ukumelana kwamakhemikhali okuhle kakhulu, okuyivumela ukuthi isebenze ngokuthembekile ngisho nasezindaweni zamakhemikhali ezinokhahlo. Lokhu kuyenza ifaneleke ikakhulukazi ukusetshenziswa ezinqubweni ezibandakanya ukufakwa, ukufakwa, kanye nokwelashwa kwezinga lokushisa eliphezulu, lapho ukugcinwa kobuqotho besikebhe esiyisinkwa esilucwecwe kubalulekile ukuze kuqinisekiswe ukuphuma kwekhwalithi ephezulu.

| Izakhiwo ezibonakalayo ze-Recrystallized Silicon Carbide | |

| Impahla | Inani Elijwayelekile |

| Izinga lokushisa lokusebenza (°C) | 1600°C (nomoya-mpilo), 1700°C (ukunciphisa imvelo) |

| Okuqukethwe kwe-SiC | > 99.96% |

| Mahhala Si okuqukethwe | < 0.1% |

| Ukuminyana ngobuningi | 2.60-2.70 g/cm3 |

| I-porosity ebonakalayo | < 16% |

| Amandla okucindezela | > 600 MPa |

| Amandla okugoba abandayo | 80-90 MPa (20°C) |

| Amandla okugoba ashisayo | 90-100 MPa (1400°C) |

| Ukunwetshwa kwe-Thermal @1500°C | 4.70 10-6/°C |

| I-Thermal conductivity @1200°C | 23 W/m•K |

| I-Elastic module | 240 GPA |

| Ukumelana nokushaqeka okushisayo | Kuhle ngokwedlulele |