2. Inqubo Yokuhlola

2.1 Ukuphulukiswa Kwefilimu Enamathelayo

Kwaphawulwa ukuthi ukudala ngokuqondile ifilimu ye-carbon noma ukubopha ngephepha le-graphiteAma-wafers e-SiCehlanganiswe nge-adhesive kwaholela ezinkingeni eziningana:

1. Ngaphansi kwezimo ze-vacuum, ifilimu yokunamathisela ivuliweAma-wafers e-SiCyakha ukubukeka okufana nesikali ngenxa yokukhululwa komoya okuphawulekayo, okwaholela ekuqineni kwendawo. Lokhu kuvimbele izendlalelo zokunamathisela ekuhlanganeni kahle ngemuva kwe-carbonization.

2. Ngesikhathi sokuhlangana, iisilucwecwanakufanele ibekwe ephepheni le-graphite ngesikhathi esisodwa. Uma ukubekwa kabusha kwenzeka, ingcindezi engalingani inganciphisa ukufana kokunamathelayo, kube nomthelela omubi kwikhwalithi yokubopha.

3. Emisebenzini ye-vacuum, ukukhululwa komoya ovela kungqimba lokunamathisela kubangele ukuxebuka kanye nokwakheka kwama-void amaningi ngaphakathi kwefilimu yokunamathisela, okuholela ekushiyekeni kwesibopho. Ukubhekana nalezi zinkinga, pre-omisa ingcina phezukwe-waferindawo yokubopha usebenzisa ipuleti elishisayo ngemuva kokugcotshwa kwe-spin kunconywa.

2.2 Inqubo Yekhabhoni

Inqubo yokwenza ifilimu ye-carbon ku-I-SiC seed waferfuthi ukuyibopha ephepheni le-graphite kudinga i-carbonization ye-adhesive layer at lokushisa elithile ukuze kuqinisekiswe ukubopha okuqinile. I-carbonization engaphelele ye-adhesive layer ingaholela ekuboleni kwayo ngesikhathi sokukhula, ikhiphe ukungcola okuthinta ikhwalithi yokukhula kwekristalu. Ngakho-ke, ukuqinisekisa ukuthi i-carbonization ephelele ye-adhesive layer ibalulekile ekuxhumaneni okuphezulu. Lolu cwaningo luhlola umphumela wokushisa ku-adhesive carbonization. Ungqimba olufanayo lwe-photoresist lusetshenziswe ku-isilucwecwanaphezulu bese ifakwa esithandweni seshubhu ngaphansi kwevacuum (<10 Pa). Izinga lokushisa liye lanyuswa lafinyelela emazingeni asethiwe (400℃, 500℃, kanye no-600℃) futhi agcinwa amahora angu-3-5 ukuze kuzuzwe carbonization.

Ukuhlola kukhonjisiwe:

Ku-400 ℃, ngemva kwamahora angu-3, ifilimu yokunamathisela ayizange ifake i-carbonize futhi ibonakale ibomvu emnyama; alukho ushintsho olukhulu olubonwe ngemuva kwamahora ama-4.

Ngo-500℃, ngemva kwamahora angu-3, ifilimu yaphenduka yaba mnyama kodwa yasakaza ukukhanya; alukho ushintsho olubalulekile ngemuva kwamahora ama-4.

Ngo-600 ℃, ngemva kwamahora angu-3, ifilimu yaphenduka yaba mnyama ngaphandle kokudluliselwa kokukhanya, okubonisa ukuthi i-carbonization ephelele.

Ngakho-ke, izinga lokushisa elifanele lokubopha lidinga ukuba ≥600℃.

2.3 Inqubo Yokufaka Isicelo Esinamathelayo

Ukufana kwefilimu yokunamathisela kuyinkomba ebalulekile yokuhlola inqubo yokufaka isicelo sokunamathela kanye nokuqinisekisa ungqimba olufana lokubopha. Lesi sigaba sihlola isivinini esilungile sokujikeleza nesikhathi sokumboza sobukhulu befilimu enamathelayo. Ukufana

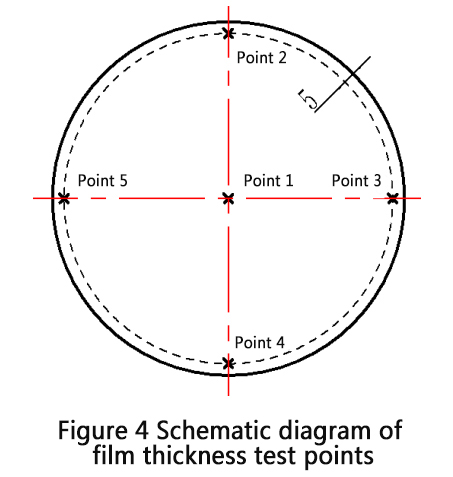

Ubukhulu befilimu buchazwa njengesilinganiso sobukhulu befilimu obuncane i-Lmin ukuya kubukhulu befilimu obungu-Lmax ngaphezu kwendawo ewusizo. Amaphuzu amahlanu ku-wafer akhethiwe ukukala ukushuba kwefilimu, futhi ukufana kubalwa. Umfanekiso 4 ukhombisa amaphuzu okulinganisa.

Ukuze uthole ukuhlangana okuphezulu phakathi kwewafa ye-SiC nezingxenye ze-graphite, ukujiya kwefilimu enamathelayo okuncanyelwayo kungu-1-5 µm. Kukhethwe ugqinsi lwefilimu olungu-2 µm, olusebenza kukho kokubili ukulungiswa kwefilimu yekhabhoni kanye nezinqubo zokuhlanganisa iphepha eliyisicwecwana/legraphite. Imingcele ye-spin-coating efanelekile ye-adhesive carbonizing ingama-15 s ku-2500 r/min, kanye ne-adhesive ebophayo, i-15 s ku-2000 r/min.

2.4 Inqubo Yokuhlanganisa

Ngesikhathi sokuhlanganiswa kwe-wafer ye-SiC nephepha le-graphite/graphite, kubalulekile ukuqeda ngokuphelele umoya namagesi aphilayo akhiqizwa ngesikhathi se-carbonization kusuka kungqimba lokubopha. Ukuqedwa kwegesi okungaphelele kubangela ama-voids, okuholela kungqimba lwebhondi engaminyene. Umoya kanye namagesi aphilayo angakhishwa kusetshenziswa ipompo likawoyela eliwumshini. Ekuqaleni, ukusebenza okuqhubekayo kwepompo yemishini kuqinisekisa ukuthi igumbi le-vacuum lifinyelela umkhawulo walo, okuvumela ukukhishwa komoya okuphelele kusuka kungqimba lokubopha. Ukukhuphuka kwezinga lokushisa ngokushesha kungavimbela ukuqedwa kwegesi okufika ngesikhathi ngesikhathi se-carbonization enezinga lokushisa eliphezulu, kwenze izikhala kungqimba oluyisibopho. Izakhiwo zokunamathisela zibonisa ukuphuma okubalulekile kokuthi ≤120℃, zizinza ngaphezu kwaleli zinga lokushisa.

Ingcindezi yangaphandle isetshenziswa ngesikhathi sokubopha ukuze kuthuthukiswe ukuminyana kwefilimu yokunamathisela, kube lula ukuxoshwa komoya kanye namagesi aphilayo, okuholela ekutheni kube nongqimba oluphezulu lokubopha.

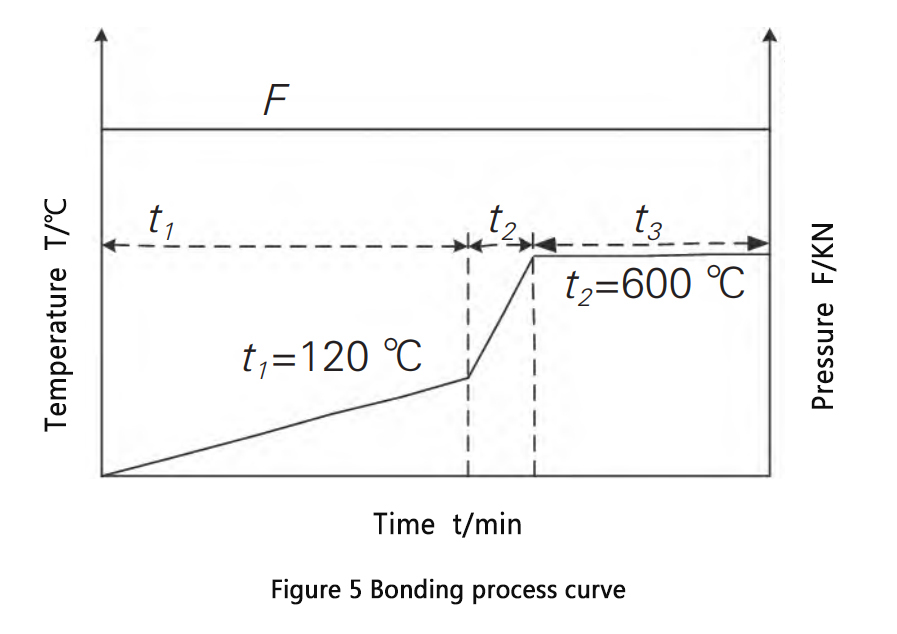

Kafushane, ijika lenqubo yokubopha eliboniswe kuMfanekiso 5 yathuthukiswa. Ngaphansi kwengcindezi ethile, izinga lokushisa liyakhushulelwa kuzinga lokushisa elikhipha umoya (~120℃) futhi libanjwe kuze kuqedwe ukukhipha umoya. Khona-ke, izinga lokushisa liyenyuka liye ezingeni lokushisa le-carbonization, eligcinwe isikhathi esidingekayo, kulandelwa ukupholisa kwemvelo ekamelweni lokushisa, ukukhululwa kwengcindezi, nokususwa kwe-wafer eboshwe.

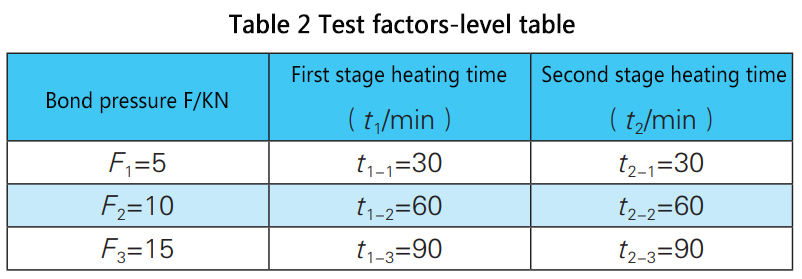

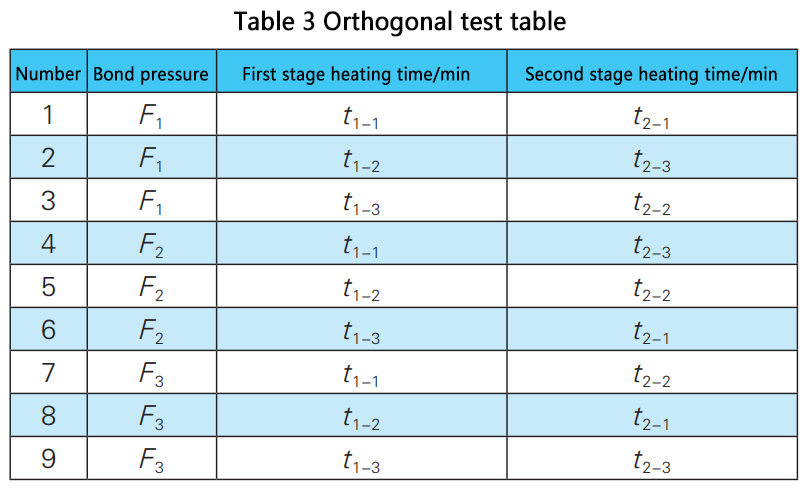

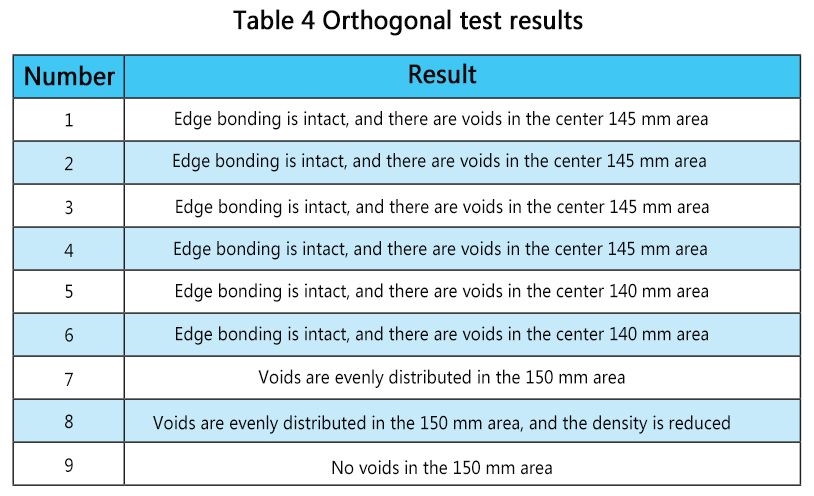

Ngokwesigaba 2.2, ifilimu yokunamathisela idinga ukwenziwa ikhabhoni ku-600℃ amahora angaphezu kwama-3. Ngakho-ke, ku-bonding process curve, i-T2 isethwe ku-600℃ kanye ne-t2 kuya kumahora angu-3. Amanani alungile ejika lenqubo yokuhlanganisa, anqunywa ngokuhlolwa kwe-orthogonal okutadisha imiphumela yokucindezela kokubopha, isikhathi sokushisa sesigaba sokuqala esingu-t1, nesikhathi sokushisa sesigaba sesibili esingu-t2 emiphumeleni yokubopha, kuboniswa kuThebula 2-4.

Imiphumela ikhonjisiwe:

Ngengcindezi yokubopha engu-5 kN, isikhathi sokushisa sibe nomthelela omncane ekubopheni.

Ku-10 kN, indawo engenalutho kusendlalelo sokubopha yehla ngokushisisa okude kwesigaba sokuqala.

Ku-15 kN, ukunweba ukushisisa kwesigaba sokuqala kunciphisa kakhulu ama-voids, ekugcineni ukuwaqeda.

Umthelela wesikhathi sokushisa wesigaba sesibili ekuhlanganiseni awuzange ubonakale ekuhlolweni kwe-orthogonal. Ukulungisa ingcindezi yebhondi ku-15 kN kanye nesikhathi sokushisa sesigaba sokuqala ngamaminithi angu-90, izikhathi zokushisa zesigaba sesibili ezingama-30, 60, kanye nama-90 min konke kubangele izendlalelo ezihlangene eziminyene ezingenalutho, okubonisa ukuthi isikhathi sokushisa sesigaba sesibili umthelela omncane ekuhlanganiseni.

Amanani afanelekile ejika lenqubo yokubopha yilawa: ingcindezi yokubopha i-15 kN, isikhathi sokushisa kwesigaba sokuqala esingu-90 min, izinga lokushisa lesigaba sokuqala ngu-120 ℃, isikhathi sokushisa sesigaba sesibili 30 min, izinga lokushisa lesigaba sesibili lingu-600 ℃, nesikhathi sokubamba sesigaba sesibili. 3 amahora.

Isikhathi sokuthumela: Jun-11-2024